Thermal fault pattern - module idling: causes and detection

You can think of an idle module as a team member who is present but does not perform any tasks – it looks ready for use but does not contribute to the overall performance. This state is barely recognisable visually, but consequently leads to yield losses and can indicate electrical connection errors or defective components. If this fault remains undetected, the yield loss adds up over the years. Using drone thermography, these non-working PV modules can be detected quickly and precisely – before they cause economic damage.

What does ‘module idle’ mean?

A PV module is idle if it is not actively connected to the circuit – this can be the case, for example, if the module was forgotten to be connected to the string during installation. Another example is when all bypass diodes of a module are in conductive state. In both examples, the module is idle, which means that the module in question is not supplying any energy.

Possible causes of an idle module:

Unconnected or incorrectly installed modules

All bypass diodes are in conductive state, bypassing the internal substrings in the module.

3. defective module optimiser within a SolarEdge system where power optimisers, not modules, are connected in series.

Defective module inverter within systems in which each module has its own inverter, e.g. Enphase module inverters.

Thermographic detection with the drone

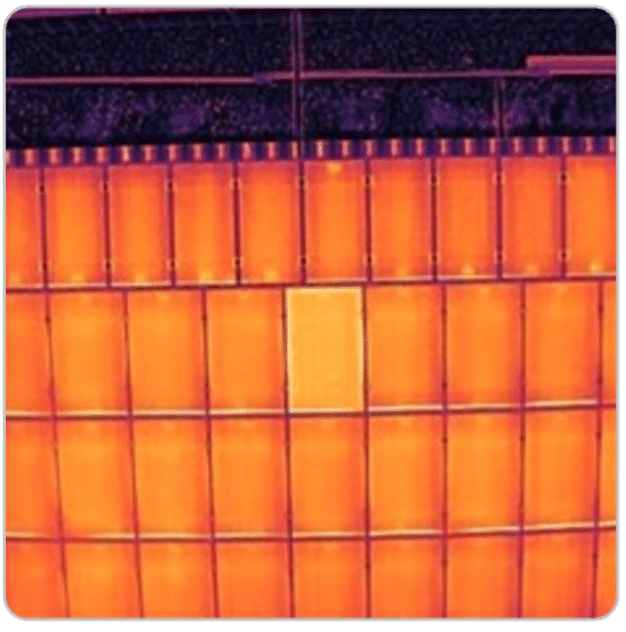

An idle module is thermally indicated by a homogeneously higher temperature than the neighbouring active modules. While active modules have a reduced surface temperature due to current flow, the affected module remains warmer.

Consequences of a module in idle mode

⚡ Power loss due to the inoperative PV module 💸 Economic damage due to loss of yield

Advantages of drone thermography

Fault patterns such as modules that are idle can be detected reliably and quickly, even in large systems. Depending on the system, this fault pattern can also be detected by measuring the open-circuit voltage or by analysing it in the monitoring portal. However, the advantage of drone thermography is that troubleshooting is very efficient and fast. In addition, drone thermography offers the advantage that no intervention in the operation is necessary; the inspection takes place without system downtime.

Conclusion

A single module running idle may seem small – but over its lifetime, yield losses add up. Regular thermographic inspections with drones help to quickly identify such faults, rectify them in a targeted manner and ensure efficient system operation.

📢 More interesting Insights?

🔗 Subscribe to the Photovoltaik Vision WhatsApp channel & newsletter!

Author and expert: Jan Wannenwetsch