Full sun, half the yield - where is the energy lost?

Just imagine: A sunny day, the display of your PV system shows a stable output – everything seems perfect. ☀

But when the statement arrives at the end of the month, they are in for a surprise:

The yields are significantly lower than expected.

No error, no warning – and yet valuable energy is lost day after day.

The reason? - An idle string.

Silent, invisible, but with serious consequences for your earnings.

Such errors often remain undetected for months, but can cause financial losses or even safety risks.

The solution? - Drone thermography.

It makes invisible weak points visible – quickly, reliably and without long downtimes.

What is an ‘idle string’?

A photovoltaic string consists of several solar modules connected in series, which together generate direct current.

If a string is idle, the circuit is interrupted – whether due to a faulty connection, a defective inverter or a damaged generator connection box.

The affected modules then no longer contribute to power generation.

Common causes of an open-circuit string

- Damaged or loose plug connections – the current flow is interrupted.

- Defective string fuses – DC fuses that protect PV modules can fail.

- Short circuits or thermal overloads – components in junction boxes fail.

- Inverter faults – individual or multiple strings can fail.

- Defective or deactivated generator junction boxes – faulty connections between strings & inverters can cause strings to idle.

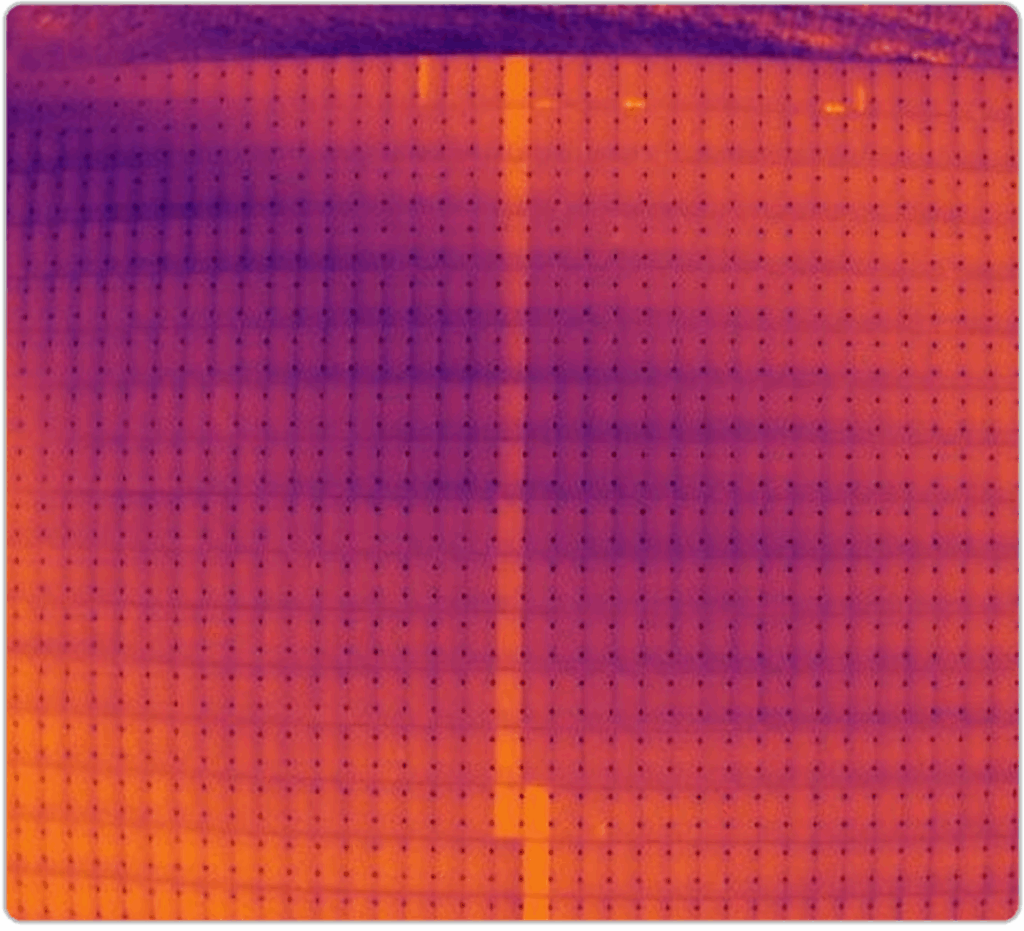

How do you recognise an idle string?

🔥 Warmer temperature pattern – Non-working strings heat up more because less radiant energy is converted into electricity.

📷 Thermography as a solution – In thermography, they appear warmer than neighbouring, functioning strings. For clear temperature differences, an irradiation of > 600 W/m² is required.

Why is drone thermography ideal for fault diagnosis?

✅ Fast and large-scale inspection – drones capture PV fields and roofs in just a few minutes.

✅ No system downtime – inspection takes place during operation.

✅ Precise fault detection – empty strings are identified without time-consuming individual measurements.

The consequences of an idle string

🚨 Power loss – lower yields.

🔥 Safety risks – defective cables or connections can lead to thermal problems or even electric arcs.

📢 More interesting Insights?

🔗 Subscribe to the Photovoltaik Vision WhatsApp channel & newsletter!

Author and expert: Jan Wannenwetsch